3D Potter|3D Potterbot Scara H.D. (Heavy Duty)

Our largest model for 3D ceramic and paste printing is the 3D Potterbot Scara Heavy Duty. It is capable of printing multiple large objects at the same time. This model MUST be combined with a Continuous Flow hopper to print, but this broadens its printing capability to include Structures, walls, and a variety of other large-format applications.

The Continuous Flow Pump/hopper is available for purchase separately.

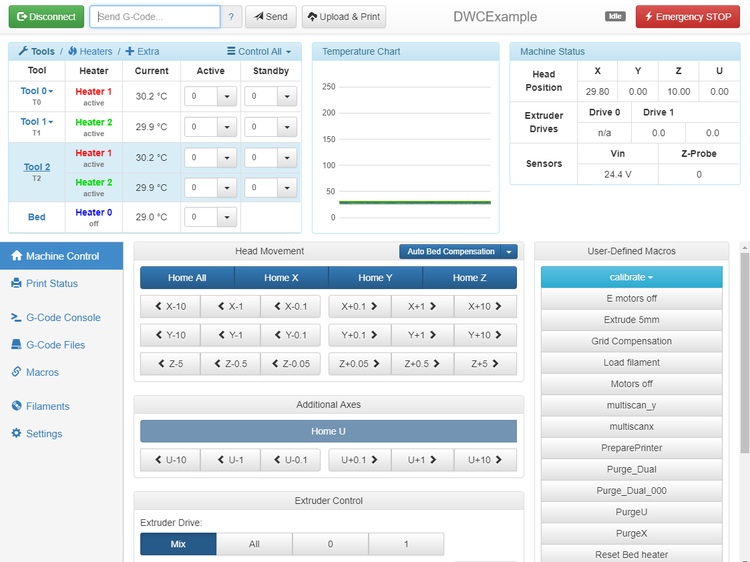

Note: Complete control via a web interface enabled, with no apps or software to install. There are non-WiFi versions available; please contact us if you require this type of connection (Ethernet connection).

Main Features of the 3d PotterBot Scara H.D.

The Scara H.D. V4520 is our massive viable large-scale ceramic 3D printer that uses real clay and has a much larger build volume than the Scara Standard or Scara H.D..

The advanced design and sturdy construction ensure dependability and stability in a variety of harsh work environments.

As a purpose-built industrial clay/ceramic printer, this printer MUST be used with our new large capacity continuous high-pressure hose extrusion system, as opposed to our smaller models.

Noise and Speed

The Scara H.D. is capable of extreme speeds, but when it comes to ceramic 3D printing, speed is relative. In reality, you probably don't want to go faster than 130 mm/s. Many factors influence speed, including nozzle size, layer height, and achieving good adhesion on the clay's interlayer.

The Scara H.D. is extremely quiet, allowing it to be used in any location without disturbing the surrounding environment.

Design and Construction

Only through meticulous design and robust construction techniques were we able to achieve high precision and accuracy with this large Scara arm robot. For maximum strength and rigidity, the majority of this structure is made of heavy aircraft grade 6061 aluminium with CNC and welded components.

The main rail components are made by IGUS*, a leading German manufacturer of precision guide rails. The drive motors are high-tech hybrid closed-loop stepper motors. These have on-board computers with telemetry that constantly update their position in order to achieve zero error positioning.

Drive Mechanisms

This is not a modified 3D printer; rather, it is a dedicated heavy-duty purpose-built robot. The primary drives are advanced harmonic drive units. These are the same drives that are used on large industrial robots like the ones that are now found in the majority of large manufacturing facilities.

These drives are extremely powerful, with precision movement down to fractions of a second of a degree. This means that prints will be very precise, with no backlash or jittery movements at realistic speeds. These drives are engineered for maximum rigidity and precision.

Space Required for Setup

The real benefit is that this machine can be placed on a substantial table top and begin printing immediately within a limited envelope area. You can also give it its own dedicated space for either a partial or full envelope.

The space required is primarily determined by the end-user and how much of the print envelope is used. The Scara H.D. will require direct mounting for maximum stability, whether on the table top or on the floor.

This is accomplished by using multiple screws to secure the printer to the surface it is resting on. If you choose to use a tabletop, it must be of substantial construction, with a minimum thickness of 1.5 inches "construction made of thick, heavy plywood or wood If an insufficient table is used, the printer's output will be reduced depending on the build envelope and speed at which the prints are created.

Software Requirements

There are none! The only thing needed is a web browser interface.

The Scara H.D. ceramic printer is similar to the rest of the 3D Potter line in terms of object generation. It works in the same way as any other 3D printer, requiring an STL file to be sliced by a third-party programme.

We recommend using Simplify3D and then loading the file to the printer's SD card, which can be done over WiFi.

Build Envelope

The Scara Heavy Duty has a Z height of 108 inches and a diameter of 144 inches.

Its build envelope is unique in that it can print 360 degrees with continuous rotation. This means you can build a large vessel with the printer initially residing inside it. This opens up a whole new avenue for printing small habitat structures (houses). For this potential habitat project, this is the largest and most qualified printer in our lineup.

Another one-of-a-kind feature is the ability to print multiple objects sequentially within the specified envelope. For example, you could print a specific vessel beginning on the far left side and continuing to print these vessels until there is no more space available.

User Interface (WiFi)

Duet Web Control is a fully developed Scara user interface. When you open it in a web browser, you can use it on your laptop, tablet, phone, or any other WiFi-capable device.

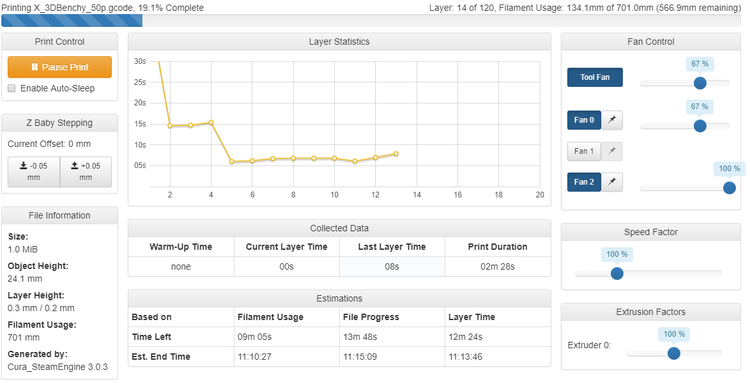

Printing Status

When a print is started, it displays information about the model that is being printed. Layer times, estimated time remaining, file information, and other details are displayed. It also allows for real-time adjustment of print and extrusion speeds.

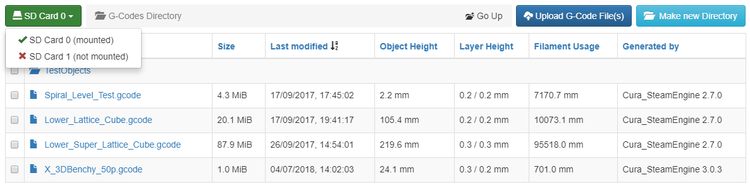

G-Code Files

The G-Code Files page allows you to upload, edit, and download g-code files for printing. A summary of the file is provided, including its size, layer height, and the program that generated it.

What’s in the Box of 3D PotterBot Scara H.D.

- 3D PotterBot 10 PRO

- Closed-loop stepper on X, Y, Z, extruder

- 2000ml extruder, 2 tubes

- 4 anodized aluminum nozzles (standard sizes: 3, 4, 5, and 6mm)

- Parts Box: Alan key set, grease, Acme driver tool, tie wraps, extra screws

- Power Supply, USB cable

What’s in the Box of 3D PotterBot Scara H.D.

- Scara H.D. (Heavy Duty)

- Closed loop stepper on X, Y, Z, extruder

- Nozzle Set

- Parts Box: Alan key set, grease, Acme driver tool, tie wraps, extra screws

- Power Supply, USB cable

Warranty of 3D Potter Printers

3D Potter offers a 1-year warranty on parts excluding consumables, ACME screw, and tubes.

We don't cover damage from: electrical surges or USB port surges, lack of cleaning and/or lubrication, the touch screen caused either by excessive force or corruption of the firmware or damage from disassembling the extruder before unloading the pressure off of the clay.